Introduction

In the fast-paced world of automotive manufacturing, where every second counts and precision is non-negotiable, high-speed CNC machining is emerging as a game-changer. As we move into 2025, the automotive industry faces unprecedented demands: electric vehicles (EVs) require lightweight, intricate components; autonomous vehicles need ultra-reliable parts; and global competition pushes for faster production without sacrificing quality. High-speed CNC machining, with its ability to churn out complex parts at lightning speeds while maintaining razor-sharp accuracy, is at the heart of this transformation. This article dives into how high-speed CNC machining is revolutionizing automotive innovation, tackling industry challenges, and paving the way for a smarter, greener future—all while keeping things precise, efficient, and, dare we say, a little exciting.

Introduction to High-Speed CNC Machining in Automotive Manufacturing

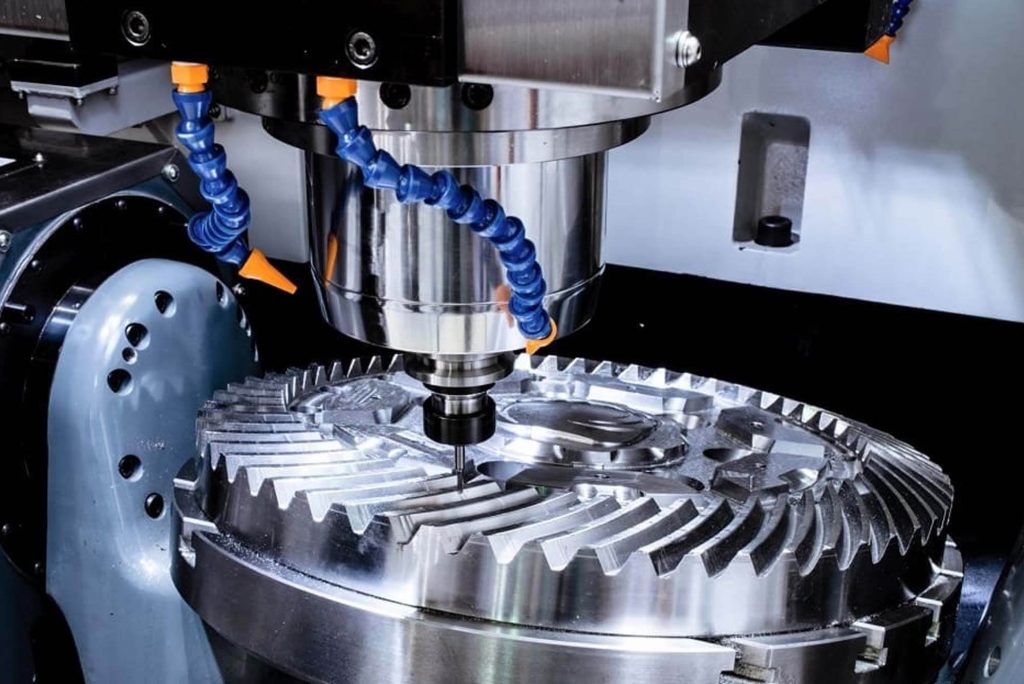

Imagine a machine that can carve out an aluminum EV battery housing in half the time it used to take, with tolerances so tight they’d make a Swiss watchmaker jealous. That’s the promise of high-speed CNC machining, a technology that’s redefining what’s possible in automotive production. Unlike traditional CNC machining, which prioritizes steady precision, high-speed CNC pushes the envelope with spindle speeds exceeding 10,000 RPM and advanced software that optimizes every cut. In 2025, this technology is critical for meeting the automotive industry’s need for speed, scalability, and sustainability. From producing lightweight chassis for EVs to crafting sensor housings for autonomous vehicles, high-speed CNC machining is the backbone of modern automotive innovation. But it’s not just about going fast—it’s about balancing that speed with unyielding precision, all while navigating labor shortages, cost pressures, and supply chain complexities.

Technical Foundations of High-Speed CNC Machining

At its core, high-speed CNC machining is about pushing machines to their limits without breaking a sweat. Picture a CNC machine with a spindle whirring at 15,000 RPM, slicing through aluminum like a hot knife through butter. The technical magic lies in a few key components:

- High-Performance Spindles: These powerhouses deliver rapid rotation, enabling faster material removal rates. Modern spindles often include liquid cooling to manage heat, ensuring consistent performance.

- Rigid Machine Frames: High-speed machining generates intense forces, so machines are built with ultra-stiff frames to minimize vibration and maintain accuracy.

- Advanced Control Systems: Software like adaptive control adjusts feed rates and spindle speeds in real time, ensuring precision even at breakneck speeds.

- Optimized Toolpaths: AI-driven algorithms calculate the most efficient cutting paths, reducing cycle times by up to 30% compared to traditional methods.

These elements work together to make high-speed CNC machining a powerhouse for automotive manufacturers. For example, producing a complex transmission gear that once took 20 minutes can now be done in 14, thanks to these advancements. But it’s not just about raw speed—precision remains the holy grail, especially for automotive parts where tolerances as tight as ±0.001 mm are standard.

Table 1: Key Technical Specifications of High-Speed CNC Machines (2025)

| Feature | Description | Impact on Automotive Manufacturing | Example Application | Performance Metric |

| Spindle Speed | 10,000–20,000 RPM, with liquid cooling for thermal stability | Reduces cycle times by 20–30% | EV battery housing | 15,000 RPM cuts aluminum 25% faster |

| Machine Rigidity | High-stiffness frames using cast iron or composite materials | Minimizes vibration, ensuring ±0.001 mm tolerances | Transmission gears | 98% reduction in vibration-related errors |

| Control Systems | Adaptive control with real-time sensor feedback | Adjusts parameters to maintain precision at high speeds | Sensor housings for autonomous vehicles | 15% fewer machining errors |

| Toolpath Optimization | AI-driven algorithms for efficient cutting paths | Shortens production time and extends tool life | Lightweight chassis components | 30% reduction in cycle time |

| Tooling Materials | Carbide and PCD tools with advanced coatings | Extends tool life by 40% under high-speed conditions | Titanium suspension parts | 50% longer tool life vs. standard tools |

Overcoming Challenges: Balancing Speed and Precision

High-speed CNC machining sounds like a dream, but it comes with its share of challenges. Push a machine too hard, and you risk vibrations that ruin surface finishes or heat buildup that warps parts. Tool wear is another headache—hard materials like titanium, common in automotive applications, can chew through tools faster than you can say “downtime.” Then there’s the programming hurdle: crafting toolpaths that maximize speed without sacrificing accuracy requires serious expertise, especially with a shrinking pool of skilled machinists.

Thankfully, the industry is fighting back with clever solutions:

- Vibration Damping: Technologies like tuned mass dampers and high-rigidity designs keep machines steady, reducing errors by up to 98%.

- Advanced Tooling: Polycrystalline diamond (PCD) and coated carbide tools extend tool life by 40%, even when machining tough alloys.

- AI Toolpath Optimization: Software like Siemens NX uses AI to streamline toolpaths, cutting cycle times by 30% while maintaining tolerances.

- Adaptive Control: Real-time sensors adjust cutting parameters, minimizing errors and ensuring consistent quality.

- Automation: Robotic arms and cobots handle material loading and unloading, reducing reliance on human operators and enabling 24/7 production.

A real-world example? A U.S. automotive supplier recently used high-speed CNC with AI-optimized toolpaths to produce EV battery housings, slashing cycle times by 25% while meeting ±0.002 mm tolerances. This balance of speed and precision is what makes high-speed CNC a cornerstone of automotive innovation.

Automotive Applications: Powering EV and Autonomous Vehicle Innovation

The automotive industry is in the midst of a revolution, and high-speed CNC machining is fueling it. Electric vehicles (EVs) demand lightweight components to maximize range, while autonomous vehicles require ultra-reliable parts for safety-critical systems. Here’s how high-speed CNC delivers:

- Electric Vehicle Components: High-speed CNC machines carve out aluminum and magnesium battery enclosures with intricate cooling channels, improving thermal management and extending battery life. For instance, a Tesla supplier uses high-speed CNC to produce battery housings 20% faster than traditional methods.

- Autonomous Vehicle Systems: Sensor housings and structural components for self-driving cars require tolerances as tight as ±0.001 mm. High-speed CNC ensures these parts are produced quickly and reliably, supporting rapid prototyping for new designs.

- Lightweighting: Machining carbon-fiber composites and titanium for chassis and suspension parts reduces vehicle weight, boosting fuel efficiency. A UK manufacturer recently used high-speed CNC to produce composite chassis components with a 15% weight reduction.

- High-Volume Production: Engine blocks, transmission gears, and brake components are churned out at scale with high-speed CNC, meeting global demand while maintaining quality.

Table 2: High-Speed CNC Machining Applications in Automotive (2025)

| Application | Material | CNC Machining Advantage | Production Impact | Industry Example |

| EV Battery Housings | Aluminum, Magnesium | Fast machining of cooling channels, ±0.002 mm tolerance | 20% faster production, 10% better thermal performance | Tesla supplier, U.S. |

| Sensor Housings | Stainless Steel, Aluminum | High precision for autonomous vehicle reliability | 15% reduction in prototyping time | Waymo component manufacturer, U.S. |

| Lightweight Chassis | Carbon-Fiber Composites | Smooth finishes for aerodynamic performance | 15% weight reduction, 25% faster machining | Jaguar Land Rover supplier, UK |

| Transmission Gears | Alloy Steel | High-speed production with tight tolerances | 30% increase in throughput | Ford supplier, Canada |

| Brake Components | Cast Iron, Aluminum | Consistent quality in high-volume production | 20% cost reduction per part | GM supplier, U.S. |

Emerging Technologies Enhancing High-Speed CNC Machining

High-speed CNC machining isn’t standing still—it’s getting a turbo boost from emerging technologies. In 2025, the integration of AI, IoT, and hybrid manufacturing is taking CNC to new heights:

- AI and Machine Learning: AI predicts tool wear and optimizes cutting parameters, reducing downtime by up to 40%. For example, a Canadian automotive supplier uses AI to monitor spindle performance, catching issues before they halt production.

- IoT and Industry 4.0: IoT sensors track machine health in real time, feeding data to cloud platforms for remote monitoring. This has cut maintenance costs by 25% for some U.S. manufacturers.

- Hybrid Manufacturing: Combining high-speed CNC with additive manufacturing (e.g., 3D printing) allows for rapid prototyping and finishing of complex parts. DMG MORI’s LASERTEC series, for instance, produces EV components with 20% less material waste.

- Digital Twins: Virtual replicas of CNC machines simulate processes in real time, catching errors before they happen. A UK supplier reported a 15% reduction in scrap rates using digital twins.

These technologies don’t just make high-speed CNC faster—they make it smarter, greener, and more reliable, perfectly aligned with the automotive industry’s push for innovation.

Addressing Industry Pain Points with High-Speed CNC

The automotive industry faces a trifecta of challenges: labor shortages, cost pressures, and supply chain disruptions. High-speed CNC machining offers practical solutions:

- Labor Shortages: With 25% of U.S. manufacturing workers over 55, the skills gap is real. High-speed CNC machines with user-friendly interfaces and automation (e.g., robotic tool changers) reduce the need for expert operators. Training programs are also helping, with companies like Haas Automation offering online courses to upskill workers.

- Cost Pressures: High-speed CNC cuts per-part costs by speeding up production and extending tool life. Tax incentives, like the U.S. Manufactured in America Act, further offset equipment costs, making high-speed CNC a smart investment.

- Supply Chain Reliability: Reshoring CNC operations to the U.S., UK, and Canada minimizes delays and risks. A Canadian supplier, for instance, reduced lead times by 20% by bringing high-speed CNC in-house.

Table 3: Impact of High-Speed CNC Machining on Industry Pain Points (2025)

| Pain Point | High-Speed CNC Solution | Quantifiable Benefit | Example | Region |

| Labor Shortages | Automation, user-friendly CNC interfaces | 30% reduction in operator dependency | Robotic loading at GM supplier | U.S. |

| Cost Pressures | Faster cycle times, longer tool life | 20% lower per-part costs | Ford transmission gear production | Canada |

| Supply Chain Disruptions | Reshoring with high-speed CNC | 20% shorter lead times | Jaguar Land Rover localized production | UK |

| Tool Wear | Advanced coatings, AI-driven optimization | 40% longer tool life | Titanium machining for EV components | U.S. |

| Energy Costs | Energy-efficient CNC machines | 15% reduction in energy consumption | Aluminum machining for battery housings | UK |

Sustainability and Efficiency in Automotive CNC Machining

In 2025, sustainability isn’t just a buzzword—it’s a mandate. High-speed CNC machining is stepping up with energy-efficient machines that cut power consumption by 15%. Recycling aluminum chips from machining processes is another win, with some U.S. shops recovering 90% of scrap material. Hybrid manufacturing further reduces waste by combining additive and subtractive processes, aligning with the automotive industry’s push for greener production. For example, a UK supplier producing EV chassis parts reported a 20% reduction in material waste using hybrid CNC systems, all while meeting stringent environmental regulations.

The Future of High-Speed CNC Machining in Automotive Innovation

Looking ahead, high-speed CNC machining is poised for explosive growth. The global CNC machine market is projected to hit $137.64 billion by 2031, with automotive driving much of the demand. Next-generation spindles reaching 20,000 RPM and digital twins for real-time process optimization are on the horizon. Workforce development is also critical—partnerships between manufacturers and technical schools are training the next generation of CNC operators. Sustainability will remain a focus, with energy-efficient machines and recycled materials becoming standard. As EVs and autonomous vehicles dominate the automotive landscape, high-speed CNC machining will be the unsung hero, delivering the precision and speed needed to keep the wheels of innovation turning.

Conclusion

High-speed CNC machining is more than a manufacturing tool—it’s a catalyst for automotive innovation. By balancing blazing-fast production with pinpoint precision, it’s powering the creation of lighter, smarter, and more efficient vehicles. From EV battery housings to autonomous vehicle sensors, high-speed CNC is tackling the industry’s toughest challenges while embracing AI, IoT, and sustainability. For automotive manufacturers in 2025, investing in high-speed CNC isn’t just a smart move—it’s a necessity to stay ahead in a competitive, fast-evolving market.

FAQ:

- What is high-speed CNC machining, and how does it benefit the automotive industry?

Answer: High-speed CNC machining is an advanced manufacturing process that uses computer-controlled machines with spindle speeds exceeding 10,000 RPM to cut materials rapidly and precisely. In the automotive industry, it reduces cycle times by up to 30%, enabling faster production of components like EV battery housings and transmission gears. It maintains tight tolerances (±0.001 mm), critical for autonomous vehicle sensors, and supports lightweight materials like aluminum and composites, boosting fuel efficiency and innovation.

- How does high-speed CNC machining balance speed and precision?

Answer: Balancing speed and precision in CNC machining involves advanced technologies like vibration damping, AI-optimized toolpaths, and adaptive control systems. For example, tuned mass dampers reduce vibration by 98%, ensuring smooth finishes at high speeds. AI algorithms cut cycle times by 30% while maintaining accuracy, and real-time sensors adjust cutting parameters to prevent errors, making it ideal for automotive parts requiring both speed and exactness.

- What automotive applications rely on high-speed CNC machining?

Answer: High-speed CNC machining is used for electric vehicle (EV) battery enclosures, autonomous vehicle sensor housings, lightweight chassis components, and high-volume parts like engine blocks. For instance, it machines aluminum battery housings 20% faster, improving EV thermal management. It also produces carbon-fiber chassis parts with 15% weight reduction, supporting automotive lightweighting and performance goals.

- How does high-speed CNC machining address labor shortages in automotive manufacturing?

Answer: High-speed CNC machining reduces reliance on skilled labor through automation and user-friendly interfaces. Robotic arms and cobots handle material loading, cutting operator dependency by 30%. Simplified CNC software allows less experienced workers to operate machines, while training programs, like those from Haas Automation, upskill workers, helping automotive manufacturers overcome the skills gap in 2025.

- What role do emerging technologies play in high-speed CNC machining?

Answer: Emerging technologies like AI, IoT, and hybrid manufacturing enhance high-speed CNC machining. AI predicts tool wear, reducing downtime by 40%, while IoT sensors enable real-time monitoring, cutting maintenance costs by 25%. Hybrid systems, like DMG MORI’s LASERTEC, combine CNC with 3D printing, reducing material waste by 20% for automotive prototyping and production.

- Is high-speed CNC machining sustainable for automotive production?

Answer: Yes, high-speed CNC machining supports sustainability through energy-efficient machines that reduce power consumption by 15% and recycling processes that recover 90% of aluminum chips. Hybrid manufacturing minimizes material waste, aligning with 2025’s green manufacturing goals. For example, a UK supplier cut waste by 20% using hybrid CNC for EV chassis parts, meeting environmental regulations.